In residential, commercial, and industrial HVAC systems, the shape and material of ductwork directly influence airflow efficiency, space utilization, and long-term performance. Heating and cooling rectangular metal duct pipes—typically constructed from galvanized steel—stand out as a preferred choice for their ability to balance high airflow capacity, easy installation in constrained spaces, and durable performance. Unlike round ducts (which excel in low-resistance airflow but struggle with wall/ceiling integration) or flexible ducts (which lack structural rigidity), rectangular metal ducts are engineered to meet the unique demands of modern building layouts, from tight attics to commercial drop ceilings. But what makes them ideal for heating and cooling applications? How do their design and installation impact HVAC system efficiency? This guide explores their core benefits, design principles, installation best practices, and maintenance needs.

What Are Heating and Cooling Rectangular Metal

Duct Pipes?

Heating and cooling rectangular metal duct pipes are rigid, flat-sided duct components used to transport conditioned air (heated or cooled) between HVAC units and building spaces. Their defining characteristics include:

1. Rectangular Geometry: Flat, rectangular cross-sections (e.g., 8x12 inches, 16x24 inches) that fit seamlessly against walls, ceilings, or within wall cavities—maximizing usable space in homes, offices, or retail buildings.

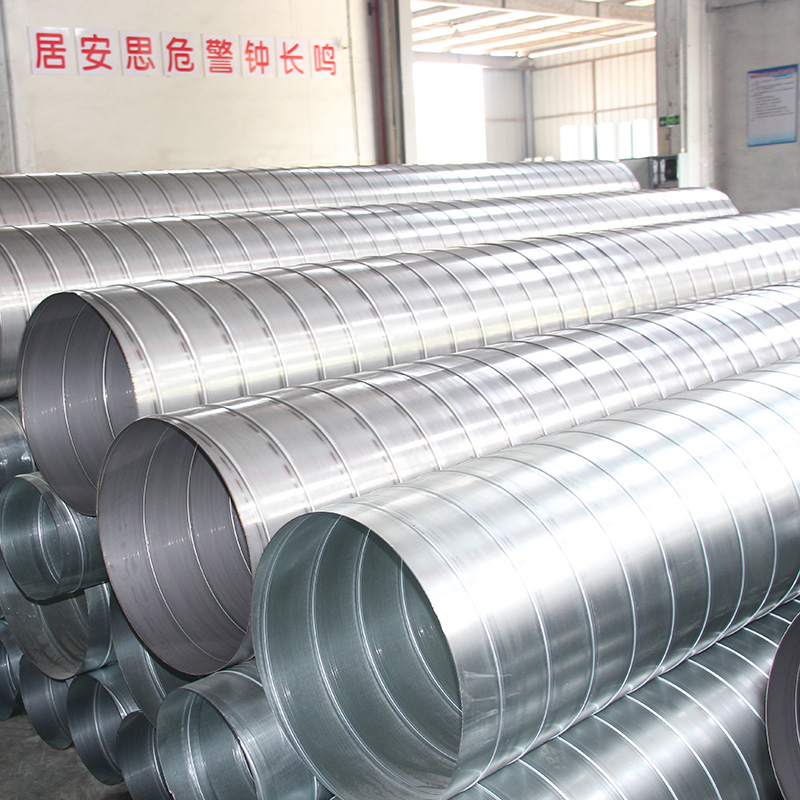

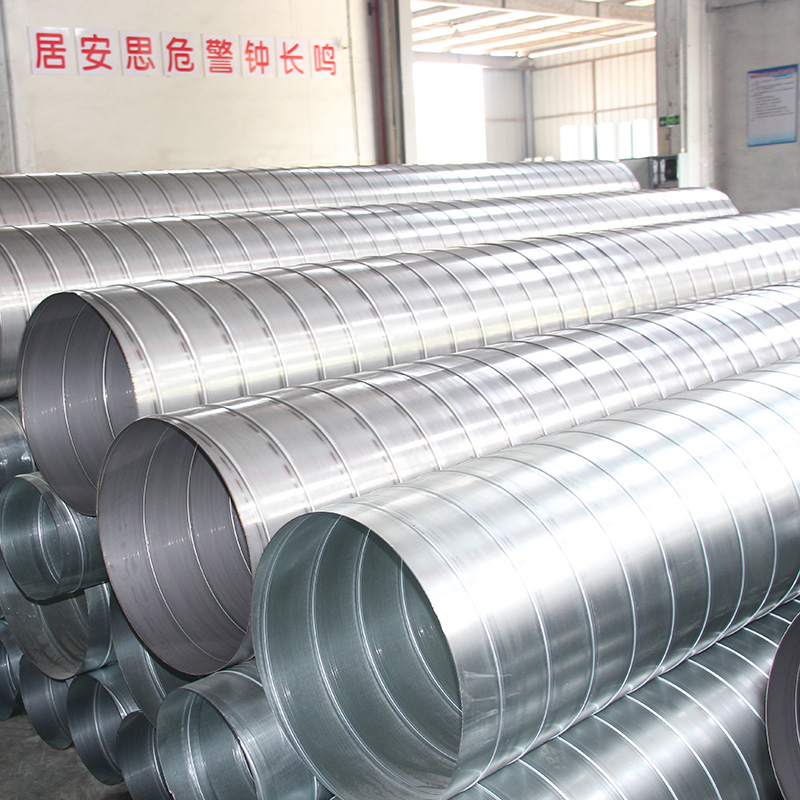

2. Metal Construction: Typically made from galvanized steel (zinc-coated for corrosion resistance) or, less commonly, aluminum. Galvanized steel is preferred for heating/cooling applications due to its strength, heat tolerance, and resistance to condensation-induced rust.

3. Modular Design: Fabricated in standard lengths (4–10 feet) with flanged or slip-and-drive connections, allowing easy assembly into larger duct networks (main trunks, branch ducts) for multi-room or multi-story buildings.

Their shape and material make them uniquely suited for distributing conditioned air in spaces where round ducts would be impractical or space-intensive.

Core Benefits of Rectangular Metal Ducts for Heating and Cooling

Rectangular metal ducts address key challenges of heating and cooling distribution, outperforming alternative duct types in critical areas:

1. Space Optimization for Modern Building Layouts

Heating and cooling ducts often need to fit within tight spaces—attics with low clearance, drop ceilings in offices, or wall cavities in residential homes. The flat profile of rectangular ducts:

- Eliminates the "bulk" of round ducts, fitting snugly against ceilings or along wall edges without reducing headroom or usable space.

- Enables installation in narrow channels (e.g., 6-inch-wide wall cavities) that round ducts of equivalent airflow capacity could not occupy.

For example, a 10x6-inch rectangular duct (which delivers ~300 CFM of airflow) fits within a standard 2x6 wall stud bay, while a round duct of the same airflow would require a 10-inch diameter—too large for most wall cavities.

2. High Airflow Capacity for Heating/Cooling Demands

Heating and cooling systems require ducts to move large volumes of air (measured in cubic feet per minute, CFM) to maintain consistent temperatures. Rectangular ducts excel here due to:

- Large Cross-Sectional Area: Wide, flat profiles (e.g., 24x12 inches) accommodate high CFM rates (1,000+ CFM) for commercial spaces (e.g., retail stores, offices) or large homes—equivalent to much larger-diameter round ducts.

- Controlled Air Velocity: Their shape allows HVAC designers to balance duct size and airflow velocity (optimal: 700–1,200 FPM for heating/cooling) to avoid noise (from high velocity) or inefficiency (from low velocity).

A 20x10-inch rectangular duct, for instance, can move 800 CFM at 760 FPM—ideal for cooling a 1,500-square-foot office—without generating the whistling noise common in undersized round ducts.

3. Easy Sealing and Air Leak Prevention

Air leaks are a major cause of heating/cooling inefficiency—losing 20–30% of conditioned air (per ENERGY STAR) and increasing utility bills. Rectangular metal ducts simplify sealing due to:

- Flat, Rigid Joints: Flanged or slip connections create smooth, even surfaces that are easy to seal with mastic or metal-backed tape (no gaps or irregularities like those in flexible ducts).

- Minimal Seam Area: Unlike round ducts (which have a single, continuous seam), rectangular ducts have four straight seams that are easier to inspect and repair.

Properly sealed rectangular ducts reduce air leakage to <5%—half the rate of poorly sealed flexible ducts—lowering heating/cooling costs by 10–15%.

4. Durability for Long-Term Heating/Cooling Use

Heating and cooling ducts operate in variable conditions: exposure to hot/cold air, condensation (from cool air in warm attics), and occasional physical contact (e.g., attic maintenance). Rectangular metal ducts:

- Resist Corrosion: Galvanized steel’s zinc coating protects against rust from condensation—a common issue in cooling applications.

- Withstand Physical Damage: Rigid metal construction resists dents, kinks, or crushing (unlike flexible ducts), ensuring airflow remains unobstructed for 20–30 years.

In contrast, flexible ducts may degrade or kink within 5–10 years, requiring costly replacement—especially in high-traffic attic or basement spaces.

Key Components of a Rectangular Metal Duct System

Heating and cooling rectangular metal duct networks rely on modular components to distribute air effectively:

| Component | Function |

|-------------------------|--------------------------------------------------------------------------|

| Main Trunk Ducts | Large rectangular ducts (e.g., 24x12 inches) that connect directly to the HVAC unit, carrying conditioned air to the building’s core. |

| Branch Ducts | Smaller rectangular ducts (e.g., 8x6 inches) that split off from main trunks to deliver air to individual rooms via supply vents. |

| Fittings | Specialized components to adjust direction or size:

- Elbows (90°/45°) for changing duct path around obstacles.

- Reducers (e.g., 16x10 → 12x8 inches) to match airflow needs of smaller branches.

- Transitions (rectangular → round) for connecting to round vents or registers. |

| Dampers | Adjustable plates within branch ducts to regulate airflow to specific rooms (e.g., closing dampers in unused bedrooms to save energy). |

| Registers/Vents | Grilled openings that cover duct outlets, directing conditioned air into rooms and allowing adjustment of airflow volume. |

Design Best Practices for Heating/Cooling Rectangular Ducts

Poorly designed ductwork can undermine even the most efficient HVAC unit. Follow these principles to optimize heating/cooling performance:

1. Size Ducts for Airflow Demand

- Calculate CFM requirements for each room (based on square footage, insulation, and climate) using HVAC load calculation tools (e.g., Manual J).

- Match duct size to CFM: Undersized ducts (too small for airflow) cause high velocity (noise, pressure loss); oversized ducts (too large) waste energy (air moves too slowly, losing heat/coolth).

Example: A 500-square-foot bedroom requires ~200 CFM of cooling—best served by a 10x6-inch rectangular branch duct.

2. Minimize Airflow Resistance

- Reduce Bends: Each 90° elbow adds ~5 feet of "equivalent length" to the duct (increasing pressure loss). Use 45° elbows where possible, and limit bends to 2–3 per branch.

- Avoid Sharp Transitions: Use gradual reducers (not abrupt size changes) to maintain smooth airflow—abrupt transitions cause turbulence and pressure loss.

- Keep Trunks Straight: Run main trunks parallel to building walls/ceilings, avoiding unnecessary detours around obstacles.

3. Seal All Joints for Efficiency

- Use mastic sealant (not duct tape, which degrades over time) on all flanged or slip connections. For high-pressure systems (e.g., commercial HVAC), add metal-backed tape over mastic for extra security.

- Test for leaks after installation using a smoke pencil or duct pressure tester—seal any gaps that allow smoke to escape.

4. Insulate for Energy Savings

- Insulate ducts in unconditioned spaces (attics, basements, crawlspaces) with fiberglass or foam insulation (R-value ≥6 for heating, R-value ≥8 for cooling).

- Use vapor barriers on insulation in cooling applications to prevent condensation from forming on duct surfaces (which can lead to rust or mold).

Installation Steps for Rectangular Metal Ducts

Proper installation ensures airflow efficiency and durability:

1. Plan the Layout:

- Map the path of main trunks and branches, avoiding obstacles (pipes, electrical wiring) and maximizing straight runs.

- Mark mounting points for hangers (galvanized steel hangers, spaced 4–6 feet apart for horizontal ducts) to support duct weight.

2. Fabricate or Source Ducts:

- Order pre-fabricated rectangular ducts (cut to size) from HVAC suppliers, or have custom ducts fabricated for non-standard spaces.

- Ensure all ducts and fittings are galvanized steel (for heating/cooling) to resist corrosion.

3. Install Main Trunks First:

- Connect the main trunk to the HVAC unit’s air handler, securing it with hangers to keep it level (prevents condensation pooling).

- Seal all joints with mastic to prevent leaks.

4. Add Branch Ducts and Fittings:

- Attach branch ducts to main trunks using reducers or transitions, ensuring alignment is straight (no kinks or misalignment).

- Install dampers in branch ducts where zoning is desired (e.g., different floors or room types).

5. Insulate and Test:

- Wrap ducts in insulation (with vapor barriers if needed) and secure with insulation tape.

- Test the system: Run the HVAC unit and check for airflow balance (use an anemometer to measure CFM at vents) and leaks.

Maintenance Tips for Long-Term Performance

To keep rectangular metal ducts operating efficiently for heating and cooling:

1. Inspect for Leaks Annually:

- Check joints, fittings, and insulation for gaps or damage. Reapply mastic to any leaking areas.

2. Clean Ducts Every 3–5 Years:

- Hire a professional to clean ducts with brush systems or compressed air, removing dust, debris, or mold (which can reduce airflow and worsen indoor air quality).

3. Check Dampers and Registers:

- Ensure dampers move freely (lubricate if stuck) and registers are not blocked by furniture or rugs.

4. Maintain Insulation:

- Replace damaged or missing insulation to prevent heat loss/gain—critical for energy efficiency in extreme climates.