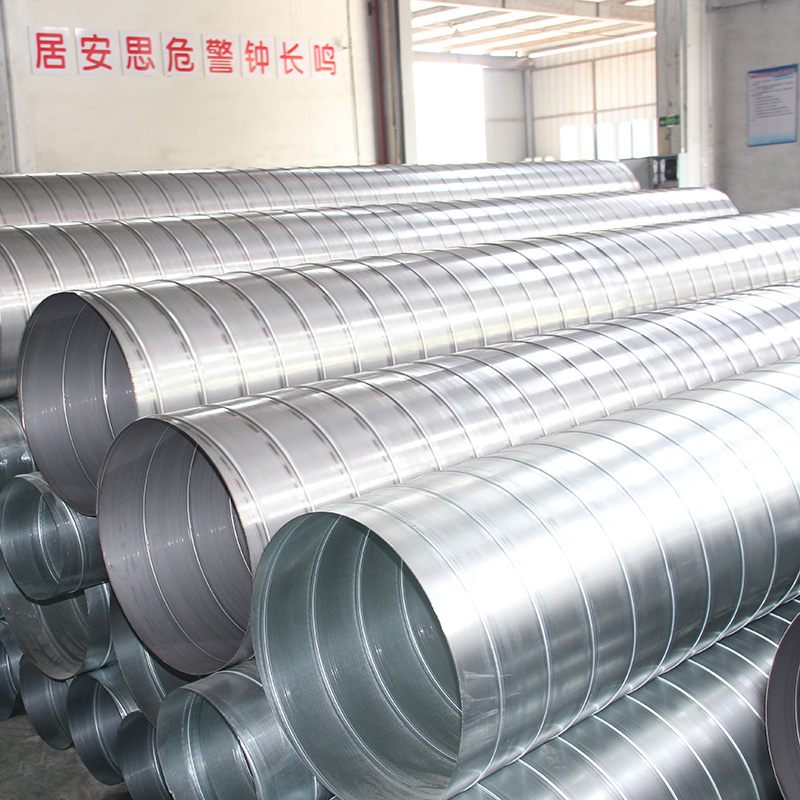

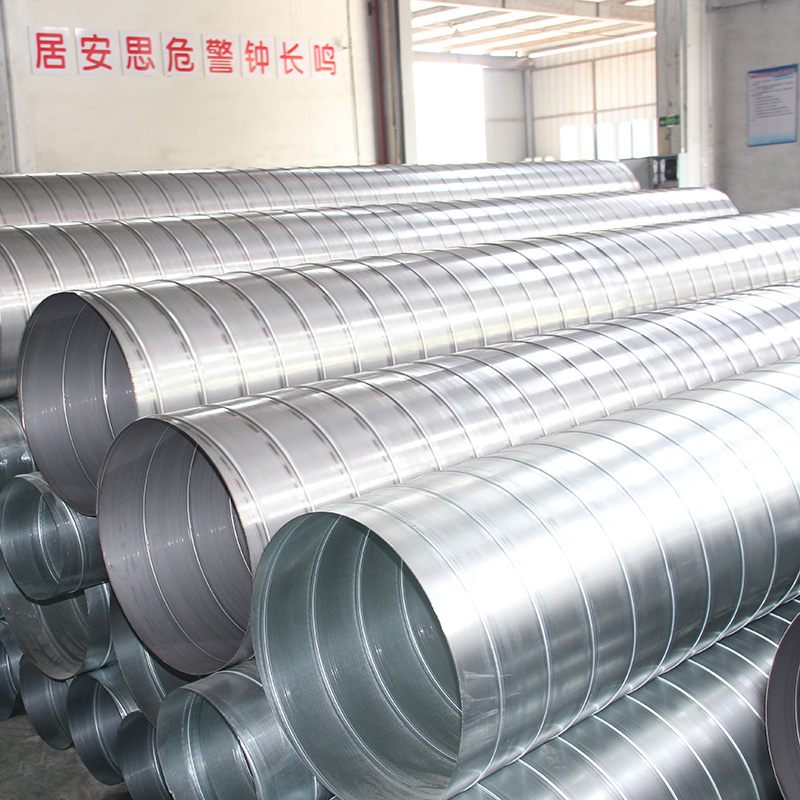

Spiral round duct—commonly referred to as spiral pipe—is a precision-engineered HVAC ductwork solution distinguished by its cylindrical geometry and continuous spiral-seam construction. Unlike rectangular or square ductwork, which relies on folded metal and mechanical joints, spiral round duct is fabricated by winding a flat metal strip (typically galvanized steel or aluminum) into a helix, with the seam locked or welded to form a leak-resistant, structurally robust tube. This design delivers unique benefits in airflow efficiency, space utilization, and cost-effectiveness, making it a preferred choice for commercial, industrial, and residential HVAC systems worldwide. Below is a technical breakdown of its engineering principles, performance advantages, application-specific use cases, installation guidelines, and comparative analysis with conventional ductwork.

The performance of spiral round duct stems from its specialized design and manufacturing process, which address key limitations of traditional duct geometries:

1.1 Construction & Manufacturing Process

- Material Selection: Primary materials include:

- Galvanized Steel (ASTM A653): The most common choice (80–90% of spiral duct applications) due to its corrosion resistance (zinc coating), high tensile strength (30–50 ksi), and cost-effectiveness. Gauges range from 26 ga (0.45 mm) for small diameters (≤8 in) to 16 ga (1.5 mm) for large diameters (≥24 in).

- Aluminum (Alloy 3003-H14): Used for lightweight or corrosion-sensitive applications (e.g., coastal buildings, food processing facilities). Offers 1/3 the density of steel and excellent resistance to salt air/moisture.

- Stainless Steel (304/316): Reserved for hygienic environments (pharmaceutical cleanrooms, commercial kitchens) where corrosion resistance and easy sanitization are critical.

- Fabrication Technique: A spiral forming machine feeds the metal strip through a series of rollers to create the helical shape. The seam is either:

- Lockformed: A mechanical interlock (no fasteners) that achieves SMACNA Class 2–3 airtightness (typical for commercial HVAC).

- Welded: TIG or laser-welded seams for SMACNA Class 4 airtightness (required for critical applications like laboratory ventilation).

1.2 Key Geometric & Aerodynamic Advantages

The cylindrical shape of spiral round duct delivers superior aerodynamic performance compared to rectangular ductwork, rooted in fluid dynamics principles:

- Reduced Pressure Drop: Round ducts have a lower aspect ratio (cross-sectional width/height = 1, vs. 2–4 for rectangular ducts) and no sharp corners, minimizing airflow turbulence. For a given airflow rate (cfm), pressure drop in spiral round duct is 20–30% lower than rectangular duct of equivalent cross-sectional area (per ASHRAE Fundamentals Handbook).

- Uniform Air Distribution: The circular cross-section ensures symmetric airflow, eliminating "dead zones" common in rectangular ducts (where air stagnates near corners). This improves diffuser performance and reduces hot/cold spots in occupied spaces.

- Higher Flow Capacity: For the same installation space (e.g., ceiling plenum height), spiral round duct can handle 15–25% more airflow than rectangular duct, as it avoids the space inefficiencies of rectangular corners.

2. Core Performance Advantages Over Conventional Ductwork

Spiral round duct outperforms rectangular, square, or snap-lock ductwork in five critical HVAC metrics:

| Advantage | Technical Rationale | Operational Impact |

|-----------|---------------------|--------------------|

| Energy Efficiency | Lower pressure drop reduces fan power consumption. For a 10,000 cfm HVAC system, spiral round duct can cut fan energy use by 15–20% annually (per DOE estimates). | A 50,000 ft² office building saves $2,000–$4,000/year in electricity costs for air handling. |

| Structural Durability | The helical seam acts as a built-in reinforcement, increasing rigidity by 30–50% compared to rectangular duct of the same gauge. Spiral duct resists sagging and deformation under its own weight or external pressure. | Service life extends to 15–20 years (vs. 10–15 years for rectangular duct) with minimal maintenance. |

| Airtightness | Lockformed seams achieve SMACNA Class 2 (≤2.0 cfm/100 ft² at 1.0 in. w.g.) as standard; welded seams reach Class 4 (≤0.5 cfm/100 ft²). Rectangular duct requires additional sealants (e.g., mastic) to meet Class 2. | Reduces air leakage by 40–60% vs. unsealed rectangular duct, lowering energy waste and improving indoor air quality (IAQ). |

| Space Efficiency | Circular cross-section fits into tighter plenums (e.g., 8 in diameter duct requires only 8 in of height, vs. 10×6 in rectangular duct which needs 10 in of height for equivalent airflow). | Enables HVAC retrofits in older buildings with limited ceiling space, avoiding costly structural modifications. |

| Cost-Effectiveness | - Material Savings: Spiral duct uses 10–15% less metal per unit of airflow (due to efficient circular geometry).<br>- Labor Savings: Fewer joints (1 joint per 10–20 ft run, vs. 1 joint per 4–8 ft for rectangular duct) reduce installation time by 25–35%. | Total installed cost is 10–20% lower than rectangular duct for most commercial projects. |

3. Application-Specific Use Cases

Spiral round duct’s versatility makes it suitable for diverse HVAC applications, with design variations tailored to environmental and functional requirements:

3.1 Commercial Buildings

- Offices, Retail, & Hospitality:

- Use Case: Supply/return air ductwork in open-plan offices, malls, or hotels.

- Rationale: Galvanized steel spiral duct balances cost, efficiency, and aesthetics. Exposed spiral duct (painted or powder-coated) is a popular design choice for industrial-modern interiors, eliminating the need for ceiling enclosures.

- Key Specs: Diameters 8–24 in, lockformed seams (SMACNA Class 2), insulated with fiberglass or foam (R-value 4.2–6.0) for sound attenuation and energy conservation.

3.2 Industrial Facilities

- Warehouses, Manufacturing Plants, & Distribution Centers:

- Use Case: High-velocity HVAC systems (1,500–3,000 fpm airflow) for large, open spaces.

- Rationale: Thick-gauge (14–16 ga) galvanized spiral duct withstands mechanical stress and high static pressure (up to 4 in. w.g.). Its low pressure drop ensures uniform airflow across 100+ ft runs, critical for temperature control in large warehouses.

3.3 Residential HVAC

- New Construction & Retrofits:

- Use Case: Ductwork for single-family homes, townhouses, or multi-family buildings (e.g., apartments).

- Rationale: Small-diameter (6–12 in) spiral duct fits into tight crawlspaces, attics, or wall cavities—avoiding the space constraints of rectangular duct. Aluminum spiral duct is ideal for coastal homes due to its corrosion resistance.

3.4 Specialized Environments

- Food Processing & Commercial Kitchens:

- Use Case: Exhaust ductwork for kitchens (to remove grease) or food storage facilities (to maintain temperature).

- Rationale: 304 stainless steel spiral duct resists grease buildup and corrosion; welded seams (SMACNA Class 4) prevent grease leaks, complying with NFPA 96 (kitchen fire safety standards).

- Laboratories & Healthcare Facilities:

- Use Case: Fume hood exhaust or cleanroom supply air ductwork.

- Rationale: Welded stainless steel spiral duct (316 for chemical labs) achieves ultra-low leakage (SMACNA Class 4) and is easy to sanitize, meeting ISO 14644-1 (cleanroom standards) and FDA requirements.

4. Installation & Quality Control Best Practices

Proper installation is critical to maximizing spiral round duct’s performance and longevity. Below are guidelines aligned with SMACNA’s *HVAC Duct Construction Standards* and ASHRAE guidelines:

4.1 Sizing & Design

- Airflow Calculations: Use ASHRAE duct sizing methods (e.g., static pressure loss method) to select duct diameter based on airflow rate (cfm) and allowable pressure drop (typically ≤0.1 in. w.g. per 10 ft run). Undersized duct causes high velocity (≥2,500 fpm) and noise; oversized duct wastes energy.

- Layout Optimization: Minimize elbows (use long-radius elbows, R/D ≥1.5) to reduce pressure drop. Avoid sharp turns or duct reductions >20% of diameter (to prevent airflow separation).

4.2 Sealing & Insulation

- Sealing: For lockformed seams (SMACNA Class 2), apply mastic sealant (ASTM C913) at all joints and penetrations. For welded seams (Class 4), perform pressure testing (manometer or smoke test) to verify leakage rates <0.5 cfm/100 ft².

- Insulation: Use fiberglass (ASTM C547) or closed-cell foam (ASTM C1129) insulation for:

- Energy conservation (R-value ≥4.2 for supply air ducts).

- Sound attenuation (reduces duct-borne noise by 10–15 dB).

- Condensation control (critical for cold air ducts in humid environments—insulation prevents moisture buildup on duct exteriors).

4.3 Support & Bracing

- Hanger Selection: Use galvanized steel hangers (clevis, strap, or trapeze) rated for the duct’s weight (including insulation). Hanger spacing follows SMACNA guidelines:

| Duct Diameter (in) | Hanger Spacing (ft) |

|---------------------|----------------------|

| ≤12 | 10 |

| 14–24 | 8 |

| ≥26 | 6 |

- Sagging Prevention: For long runs (>20 ft), use intermediate supports or tension rods to limit sagging to ≤1/4 in per 10 ft (to maintain airflow uniformity).

4.4 Noise Control

- Aerodynamic Noise: Keep airflow velocity <2,000 fpm in occupied spaces to avoid "whooshing" sounds. Use sound attenuators (fiberglass-lined or perforated) at fan outlets or near noise-sensitive areas (e.g., offices, bedrooms).

- Vibration Isolation: Install flexible connectors (neoprene or fabric) between the duct and air handler/fan to prevent vibration transmission from mechanical equipment to the duct.

5. Comparative Analysis: Spiral Round vs. Rectangular Duct

To contextualize spiral round duct’s value, below is a head-to-head comparison with rectangular duct (the most common alternative):

| Metric | Spiral Round Duct | Rectangular Duct |

|--------|--------------------|-------------------|

| Pressure Drop | 20–30% lower (per cfm) | Higher (turbulence at corners) |

| Energy Efficiency | 15–20% lower fan energy use | Higher energy consumption |

| Installed Cost | 10–20% lower (fewer joints, faster labor) | Higher (more materials, longer installation) |

| Space Requirement | 15–25% less plenum space | Requires more height/width for equivalent airflow |

| Airtightness | Class 2–4 (standard lockformed/welded) | Class 1–2 (requires additional sealants) |

| Aesthetics | Ideal for exposed installations (sleek helix design) | Requires enclosures (ceiling, soffits) for visual appeal |

| Maintenance | Fewer joints = less leakage risk; easier to clean (smooth interior) | More joints = higher leakage risk; corners trap dust/debris |