Comprehensive Analysis of Flat Welding Plate Flanges: Standards, Characteristics, Applications, and Selection Guide

Release time:2025-12-08 Visits:0

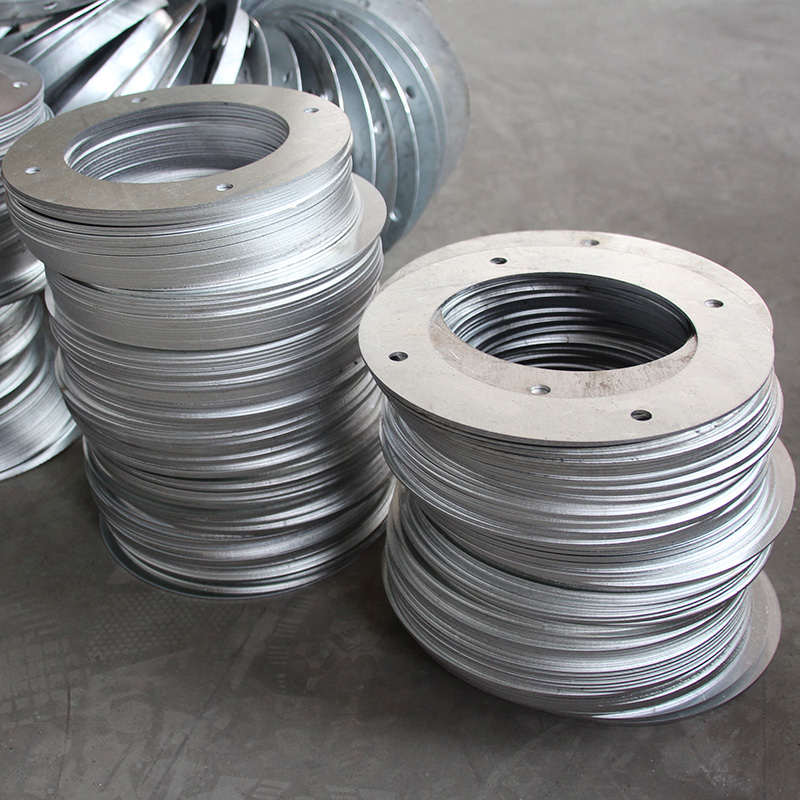

Flat welding plate flange is a pipe connection component with simple structure, low cost, and wide application. Its core feature is that the flange ring is connected to the equipment or pipeline by flat welding, and the flange itself has a flat plate structure. This design makes it the preferred component for achieving detachable connection, sealing, and local isolation functions in numerous industrial fields.

I. Main Standards and Specifications

The production and acceptance of flat welding plate flanges comply with multiple sets of national standards and industry specifications. The currently effective core national standard is GB/T 9119-2010 "Steel Pipe Flanges with Flat Welding Plate". This standard is part of the GB/T 9112~9124-2010 series standards and has been implemented since October 1, 2011, replacing the old version GB/T 9119-2000. It uniformly stipulates the types, parameters, dimensions, tolerances, and technical conditions of flanges.

In the chemical industry, HG20593-2009 is a widely adopted standard, whose technical content is coordinated with the national standard and applicable to flanges with pressure ratings from PN0.25MPa to PN4.0MPa. The mechanical industry standard JB/T 81-1994 also specifies raised face steel pipe flanges with flat welding plate.

In addition, common international standards include ANSI/ASME B16.5 from the United States, DIN from Germany, JIS B2220 from Japan, and BS 4504 from the United Kingdom, etc., to meet the needs of different regions and projects. It is worth noting that the national standard "Copper Alloy Necked Flat Welding Flanges" GB/T 15530.4-2008 also provides relevant specifications, which is under the jurisdiction of the National Technical Committee for Standardization of Pipeline Accessories.

II. Structural Characteristics and Performance

The structure of flat welding plate flange is relatively simple, and its sealing surface types mainly include full face (FF) and raised face (RF). It is connected to the pipeline through single-sided welding, and the other side is fastened with a mating flange using stud bolts. This design gives it the characteristics of low manufacturing cost and easy installation.

However, its pressure-bearing capacity is usually lower than that of butt welding or necked flanges, making it more suitable for medium and low-pressure working conditions. A variety of manufacturing materials are available, including carbon steel (such as Q235, 20#, 16Mn), stainless steel (such as 304, 316, 316L), and special alloys, to adapt to different working environments such as water, steam, gas, oil products, and various corrosive media.

III. Application Fields

With its versatility and economy, flat welding plate flanges are widely used in multiple industrial fields. These mainly include chemical industry, petroleum, construction, metallurgy, machinery manufacturing, shipbuilding, pressure vessels, water supply and drainage, and heating, ventilation systems, etc. It is a common component in pipeline systems for achieving detachable connection, sealing, and local isolation functions, playing an important role in various industrial pipeline systems.

IV. Selection Considerations

In actual engineering selection, the appropriate material and standard must be selected based on the pressure rating, sealing surface type, connection dimension standards specified in the design documents, and the corrosion requirements of the medium. The following key factors need to be considered during selection:

Pressure rating is the primary consideration in selection, and it must be ensured that the rated pressure of the flange is not lower than the maximum working pressure of the system. The selection of the sealing surface type depends on the sealing requirements; the full face is suitable for low-pressure occasions, while the raised face is more suitable for medium-pressure applications. Material selection must consider the corrosiveness of the medium, working temperature, and environmental conditions; for corrosive media, stainless steel or special alloy materials should be selected.

Standard selection is also important. It is necessary to determine whether to adopt national standards, chemical industry standards, or mechanical industry standards according to project requirements and applicable specifications. In addition, it is necessary to ensure that the flange dimensions completely match the pipeline specifications, including parameters such as inner diameter, outer diameter, and bolt hole spacing.

Finally,

flange products that meet the standard requirements must be purchased from regular channels, and non-standard products or unqualified products should be avoided to ensure the safety and sealing reliability of the connection.

By comprehensively considering these factors, the most suitable flat welding plate flange can be selected for specific applications, ensuring safe and reliable operation of the system while achieving optimal economic benefits.