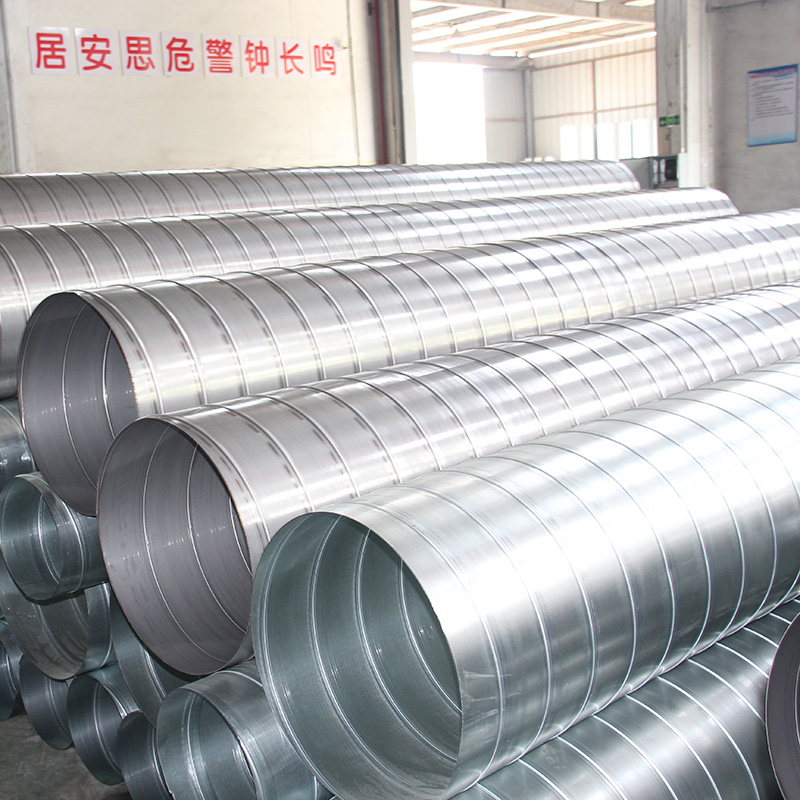

Comprehensive Analysis of Material Selection, Fabrication, and Installation Technical Specifications for Stainless Steel Air Ducts

Release time:2025-12-08 Visits:0

As a core conveying component of ventilation and air conditioning systems, the material selection, fabrication, and installation of stainless steel air ducts must strictly follow technical standards to meet requirements for strength, tightness, and corrosion resistance. The following elaborates on three aspects: material selection, process implementation, and installation control.

1. Material Selection and Specification Standards

Stainless steel air ducts mainly use 304 or 316L stainless steel plates. 304 stainless steel is suitable for general corrosive environments, with a nickel content ≥8% and chromium content ≥18%; 316L stainless steel, due to its molybdenum content ≥2.0% and carbon content ≤0.03%, is suitable for highly corrosive locations (such as chemical industry and coastal environments). The thickness of the plate shall be selected according to the classification of the long side dimension of the air duct:

- When the long side ≤500mm, the thickness ≥0.5mm;

- When the long side is 500–1120mm, the thickness ≥0.75mm;

- When the long side is 1120–2000mm, the thickness ≥1.0mm;

- When the long side >2000mm, the thickness ≥1.2mm.

For materials entering the site, material certificates and mechanical property reports shall be inspected to ensure no oxide layers, pinholes, or scratches on the surface.

2. Fabrication Process and Technical Requirements

Air duct fabrication adopts full argon arc welding technology, with both longitudinal and transverse joints requiring welding. The flange size is uniformly 15mm to ensure the joint strength reaches 1.5 times the working pressure. Welding shall use ER308 stainless steel welding wire (diameter 1.2mm), which is dried at 200°C before welding and protected with argon gas with a purity ≥99.99%.

For large-size air ducts (side length ≥1000mm), a combined scheme of ∠30×30×3 angle steel reinforcement frames and right-angle reinforcement members shall be adopted. The height of the right-angle reinforcement member is 30mm, which is fixed on the inner wall of the air duct by intermittent welding, significantly reducing the system air leakage rate (controlled within 0.5%).

3. Installation Specifications and Quality Control

Before installation, on-site conditions shall be verified: the positional deviation of structural reserved holes ≤10mm, and the hole size shall be 10mm larger on each side than the air duct section; the net height from the bottom of the air duct to the ceiling ≥200mm, and the horizontal distance from lamps and fire-fighting pipelines ≥150mm.

Flange gaskets shall be selected according to medium characteristics: acid-resistant rubber sheets (thickness 3–5mm) for corrosive environments, asbestos rubber sheets for high-temperature smoke exhaust systems, and closed-cell sponge rubber sheets for clean air conditioning systems. Supports and hangers shall be of the same material as the air duct (stainless steel or galvanized carbon steel), with a hanger diameter ≥8mm, and the angle steel specification for crossarms shall be selected according to the air duct size classification.

After the system installation is completed, a wind pressure test shall be conducted. High-pressure systems (such as process cross-blowing pipelines) shall have no leakage under a pressure ≥14000Pa. The end is usually equipped with a 304 stainless steel filter with a pore size of 0.3mm, and the ventilation area ≥50% of the pipeline cross-section, connected by flanges for easy maintenance.

4. Compliance Requirements

The fabrication, installation, and acceptance of air ducts shall strictly implement the "Code for Construction Quality Acceptance of Ventilation and Air Conditioning Engineering" (GB50243-2025) and "Technical Specification for Ventilation Ducts" (JGJ141-2004). In the design, the relative difference in pressure loss of each loop shall be guaranteed to be ≤15%, and regulatory devices shall be added if necessary; the cross-section of the air duct should be circular or rectangular with an aspect ratio ≤4, and the maximum aspect ratio shall not exceed 10.

In summary, the implementation of

stainless steel air ducts requires overall consideration of material performance, process accuracy, and installation specifications to ensure the system fully meets the standards in terms of strength, tightness, and corrosion resistance.