Ventilation Ducts: The Indispensable Respiratory System of Buildings - A Comprehensive Analysis of Functions, Materials, and Design

Release time:2025-12-08 Visits:0

Ventilation ducts are the "respiratory tract" of modern buildings, serving as the core infrastructure for ensuring indoor air quality, comfortable temperature and humidity, and a safe environment. By delivering fresh air and exhausting polluted air, they maintain a healthy and energy-efficient indoor environment.

I. Core Functions and Application Fields

Ventilation duct systems have four core functions: air supply (delivering treated air), exhaust (removing polluted air), return air (recycling air for energy efficiency), and smoke extraction (emergency smoke removal during fires). Their applications cover all building types, including residential buildings (kitchen and bathroom ventilation), commercial facilities (central air conditioning), public spaces (ventilation and smoke prevention in hospitals and subway stations), and industrial plants (dust removal and process exhaust).

II. Material Selection Guide

Materials should be comprehensively selected based on usage, environment, and cost:

- Galvanized steel sheet: High cost-performance and corrosion-resistant, suitable for most air conditioning and ventilation systems.

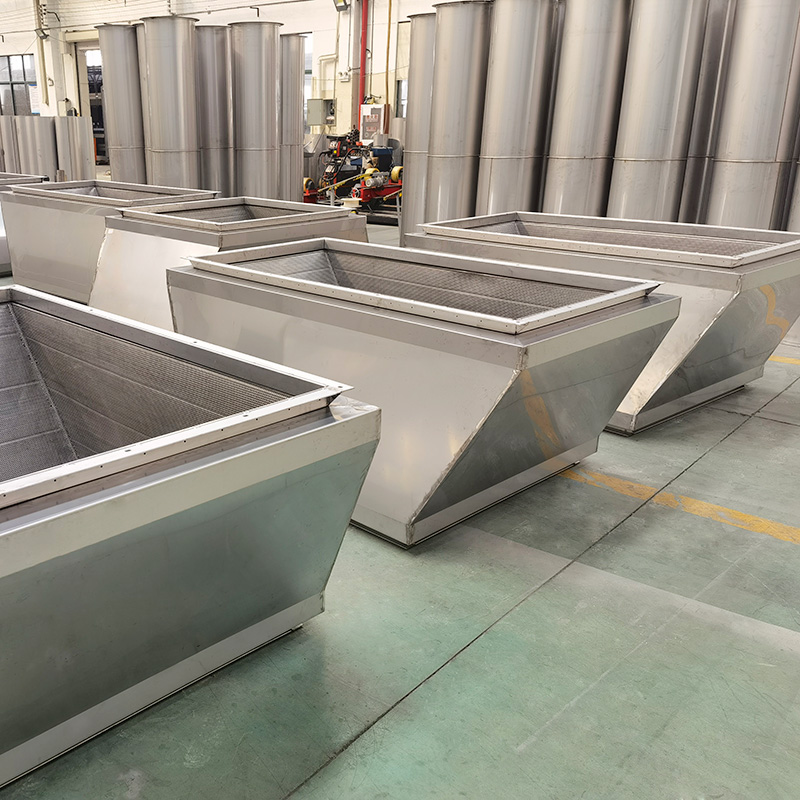

- Stainless steel: High-temperature and corrosion-resistant, used in high-demand areas such as kitchens and laboratories.

- Composite duct: Excellent thermal insulation performance, suitable for air conditioning supply systems.

- Fabric air duct: Lightweight and with uniform air supply, applicable to large spaces like gymnasiums.

- Inorganic FRP: Fireproof and moisture-resistant, specifically used in smoke prevention and exhaust systems and basements.

- PVC material: Acid and alkali corrosion-resistant, commonly found in laboratories or industrial corrosive environments.

III. System Composition and Key Components

A complete system includes duct main trunks, pipe fittings (elbows, tees), functional components (air outlets, dampers, silencers), and insulation layers. Among them, fire dampers can block fire spread during a fire, insulation layers prevent condensation and save energy, and air outlets ensure uniform air distribution.

IV. Core Principles of Design and Installation

1. Optimize pipeline layout: Reduce elbows and diameter changes to lower resistance and energy consumption.

2. Control wind speed: Main duct wind speed is typically designed to be 6-12m/s to balance noise and space efficiency.

3. Air volume balance: Adjust via dampers to ensure air volume in each area meets standards.

4. Sealing and fire protection: Strictly seal connections to prevent air leakage, and install fire dampers when passing through fire zones.

5. Thermal insulation and condensation prevention: Low-temperature ducts must be insulated to avoid structural damage from condensation water.

6. Vibration and noise reduction: Use flexible connections and silencers to control fan vibration and airflow noise.

V. Common Problems and Maintenance Suggestions

During long-term use, attention should be paid to air leakage, noise, condensation, and dust accumulation. Regular maintenance includes checking tightness, cleaning internal dust (especially in hospitals and kitchens), replacing damaged insulation layers, and testing damper functions.

The scientific design and construction of

ventilation ducts directly determine the comfort, health, and energy efficiency of buildings, making them a crucial link that cannot be ignored in modern engineering.