Analysis of Core Technical Specifications for Design and Installation of Ventilation Shaft Ducts

Release time:2025-12-08 Visits:0

Ventilation shaft ducts are a critical component of building ventilation systems, and their design and installation quality directly affect the safety, airtightness, and operational efficiency of the system. The following is an analysis of key points based on current national technical specifications:

1. Core Design Principles

The design of ventilation shaft ducts must prioritize aerodynamic performance, reducing airflow resistance through rational layout. Duct cross-sectional dimensions should be comprehensively determined based on system air volume, wind speed (typically controlled within the range of 6-12 m/s), and allowable noise levels. Fire and smoke prevention requirements are crucial: ducts passing through fire compartments must be equipped with fire dampers with a fire resistance rating of not less than 1 hour, and smoke exhaust duct materials must meet national fire resistance specifications. In terms of energy efficiency, the system air leakage rate must be strictly controlled within ≤5%, and energy consumption should be reduced by optimizing pipeline routing.

2. Material Selection Standards

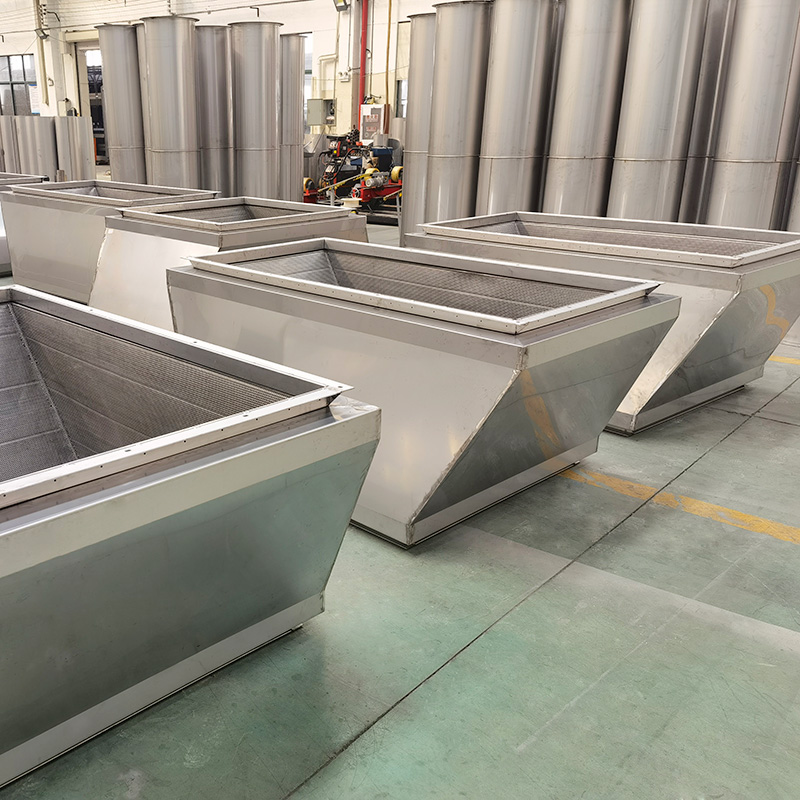

Shaft duct materials must balance strength, sealing performance, and environmental protection. Metal ducts such as galvanized steel sheets (with thickness meeting national standards), stainless steel, or aluminum sheets are suitable for corrosion-resistant or lightweight scenarios; non-metallic ducts such as fiberglass reinforced plastic or phenolic composite panels must pass combustion performance classification certification (Class A fire resistance). All materials must provide factory inspection certificates before entering the site to ensure compliance with environmental and safety requirements.

3. Installation Process Specifications

1. Support and Hanger Installation

For horizontal installation, the spacing of supports and hangers for ducts with diameter or large side length <400mm shall be ≤4m, and ≥400mm shall be ≤3m; for vertical installation, the spacing shall be ≤4m, and each riser shall have no less than 2 fixing parts. Ducts with flange-less connections require additional supports and hangers to enhance rigidity.

2. Sealing and Connection Technology

Flange connections must use flame-retardant sealant, and padding is strictly prohibited from squeezing into the duct. The connection between ducts and equipment should use 150–250mm canvas hoses, avoiding use as reducers. Removable interfaces must not be installed inside walls or floors.

3. Verticality and Safety Control

The verticality deviation of ducts must be ≤2mm/m, with a total deviation ≤20mm. Unified command is required during installation, temporary protection should be added to reserved openings, and high-altitude throwing of tools is strictly prohibited. Operators must wear safety belts and ensure no heavy objects are left inside the ducts.

4. Special Technical Requirements

- Firestopping: HVAC shaft wells must be sealed in accordance with fire codes to ensure the integrity of fire compartments.

- Maintenance and Inspection: Access panels must be reserved for equipment in suspended ceilings to facilitate later maintenance operations.

- System Testing: After installation, tightness tests and air leakage rate tests must be conducted to ensure compliance with national construction quality acceptance specifications.

In summary, the implementation of

ventilation shaft ducts must fully comply with design, material, installation, and safety standards. Through standardized operations and strict quality control, the efficient and reliable operation of the system is ensured.