Fiberglass Ducts: A Comprehensive Solution for Efficient Ventilation Systems in Modern Buildings

Release time:2025-12-08 Visits:0

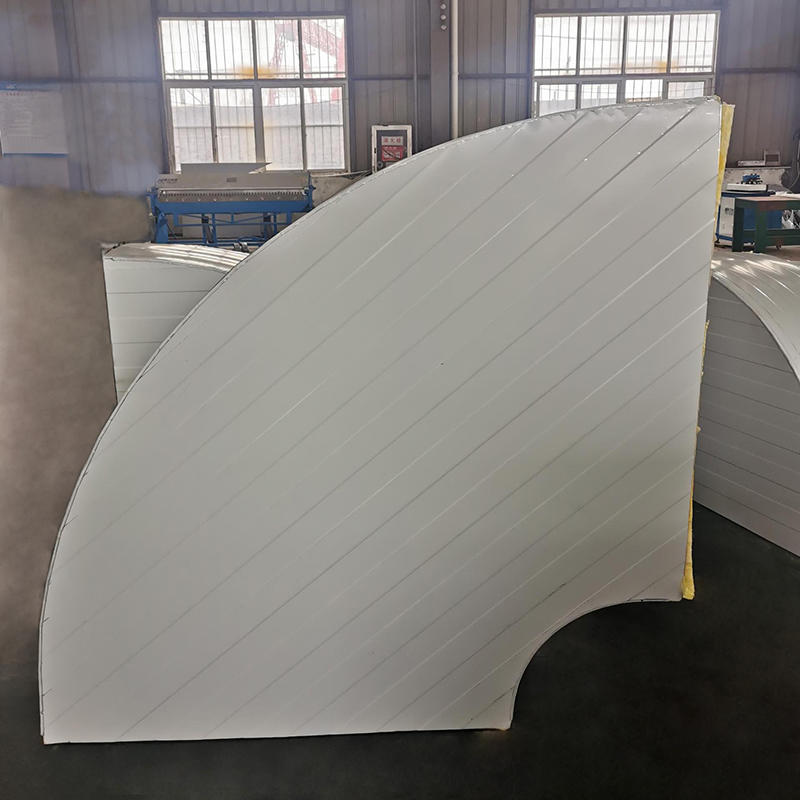

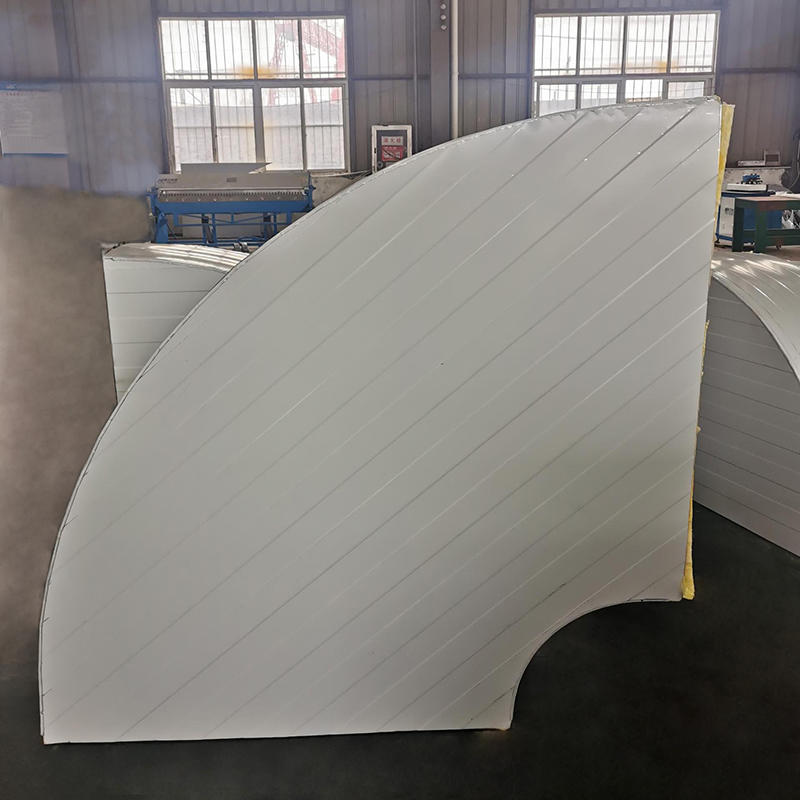

Fiberglass ducts are ventilation pipes made from centrifugal glass fiber board as the core substrate through composite processes. They are externally covered with moisture-proof aluminum foil or color steel plates, and the inner layer is often added with an antibacterial coating, forming an integrated material with both structural support and functional protection. Such ducts are widely used in HVAC systems of modern buildings, especially performing prominently in commercial buildings, public facilities, and high-end residences.

In terms of characteristics,

fiberglass ducts have multiple advantages. Firstly, they are significantly lightweight yet high-strength, with a bulk density of approximately 80 kg/m³. The light weight per unit area greatly reduces transportation and hoisting costs. The installation process adopts standardized plate cutting and bonding techniques, combined with a convex-concave groove interface design, which greatly improves construction efficiency. Secondly, fiberglass ducts possess excellent thermal insulation and energy-saving performance. The porous structure of glass fiber effectively blocks air heat exchange, reduces temperature loss during air supply, and eliminates the need for additional insulation layers, thereby lowering system energy consumption. In addition, they have outstanding sound absorption and noise reduction capabilities. The internal gaps in the fibers can absorb airflow noise, making them suitable for places with high acoustic environment requirements such as theaters, hotels, and office spaces.

Safety performance is also an important feature of fiberglass ducts. The substrate is non-combustible glass wool, meeting Class A fire protection standards, and can maintain structural stability at a high temperature of 300°C. Some products have passed formaldehyde-free environmental certification, avoiding indoor air pollution and enhancing usage safety. Meanwhile, the aluminum foil coating provides excellent moisture resistance with a moisture permeability rate close to zero. It is not prone to corrosion in long-term humid environments, has a normal service life of 10 to 30 years, and requires low maintenance.

In application scenarios, fiberglass ducts are suitable for various medium and low-pressure ventilation systems, commonly found in projects such as shopping malls, office buildings, hospitals, schools, and subway stations. Their integrated structure is particularly suitable for projects with limited ceiling space or requiring rapid construction, and can meet the needs of modern buildings for efficient and economical ventilation solutions.

It should be noted that when selecting fiberglass ducts, the wall thickness and reinforcement scheme should be determined according to air pressure, wind speed, and environmental requirements. For example, when the side length exceeds 630mm or the air pressure is higher than 500Pa, the support structure needs to be strengthened. During construction, it is necessary to standardize the sealing of cuts and joints to prevent fiber exposure or water immersion, ensuring long-term performance stability.

In conclusion, through innovations in materials and structure, fiberglass ducts achieve lightweight, energy-saving, and functional integration, making them an efficient and economical ventilation choice in modern HVAC engineering. Their comprehensive performance advantages make them a key component in improving building environmental quality.